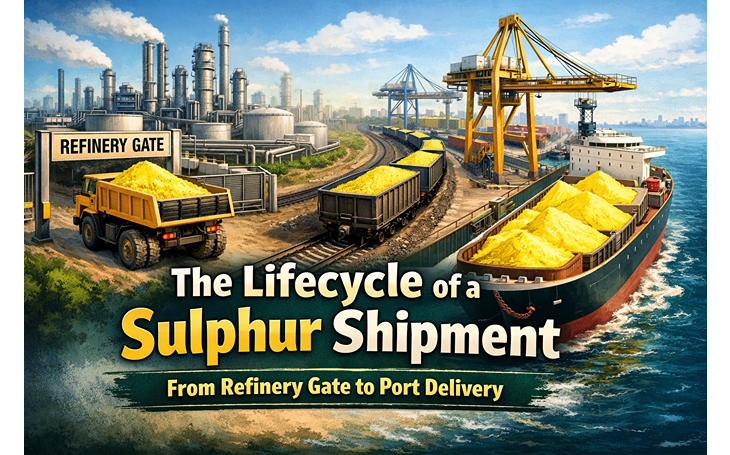

The Lifecycle of a Sulphur Shipment: From Refinery Gate to Port Delivery

Sulphur may look simple, but getting it from a refinery to an industrial buyer is a highly coordinated process. Each shipment passes through multiple checkpoints. Quality tests, safety standards, packaging rules and strict export procedures ensure that the sulphur that leaves a refinery gate arrives in the same condition at the port. Buyers who understand this lifecycle can make better decisions, avoid delays and protect their operations.

Below is a clear, step by step view of how a sulphur shipment travels through the supply chain when managed by an experienced operator.

1. Refinery Allocation and Supplier Confirmation

It begins at the refinery or industrial sulphur recovery unit. Once sulphur is formed through desulfurization, it is prepared for export. Only pre-vetted suppliers are selected. The refinery’s output history, storage layout and compliance records are reviewed. This makes sure the product meets quality expectations consistently instead of relying on a single batch test.

A formal allocation confirms the volume, the form of sulphur and the delivery window. Refinery grade sulphur balls are preferred because they pack well and remain stable during handling.

2. Stockpile Segregation and Logistics Planning

Sulphur designated for export is stored separately from internal refinery material. Segregation reduces contamination and allows sampling teams to work safely. At this stage logistics planning begins. Container availability, trucking capacity and port schedules are mapped out. Doing this early prevents bottlenecks later when deadlines tighten.

Transport routes must be selected with care. Some regions handle hazardous cargo differently, so planning avoids regulatory obstacles.

3. Sampling and Independent Quality Testing

Before moving any cargo, third party inspection agencies such as SGS or Intertek perform sampling. They collect material from multiple points in the stockpile to avoid biased results. The samples are sealed, labeled and forwarded to certified laboratories.

Testing focuses on moisture percentage, ash content and sulphur purity. High grade product typically reads around 99.5 percent, while the presence of metals or excess residue indicates poor handling or mixed batches. These reports protect the buyer and reduce disputes at the receiving end.

4. Safety Documentation and Compliance

Raw sulphur is classified as a hazardous substance. Exporters prepare Material Safety Data Sheets, cargo labels and marine safety documents according to international regulations. Documentation includes storage temperature limits, handling instructions and emergency procedures.

Compliance with IMDG rules and UN Class 4.1 guidelines gives port authorities and carriers the information they need to accept the cargo. Without these documents, containers can be held or rejected, which often leads to demurrage.

5. Packaging and Load Preparation

Packaging is one of the most overlooked stages. Sulphur balls are normally filled into jumbo bags or sealed bulk containers. Jumbo bags are designed to prevent tearing and dust leakage. Their uniform fill ratio makes stacking and palletization easier.

Every package is tagged and traced. Labeling includes product name, origin, hazard category and lot number. Skipping these basics can cause delays during port scanning or customs inspection.

6. Inland Transportation to Port

Once packaged, the shipment is loaded on trucks for inland transport. Drivers receive cargo documents and clear instructions for safe handling. Routes are often selected to avoid extreme heat or high dust environments. Good logistics operators schedule movement during favorable hours to reduce cargo exposure.

Transport crews perform quick checks on arrival to ensure the shipment was not damaged on the road. Any bag or container that shows signs of stress is isolated and inspected.

7. Port Storage and Terminal Handling

At the port terminal, sulphur shipments are stored in designated hazardous cargo sections. Storage areas maintain strict segregation from incompatible materials. Good ventilation, low ignition risk and controlled access are standard requirements.

Terminal teams use forklifts or crane lifts depending on container type. Since sulphur balls flow uniformly, unloading is smoother and faster than handling irregular lumps or flakes. This efficiency shortens waiting times and minimizes demurrage.

8. Final Verification and Vessel Loading

Before loading, final checks take place. Inspectors verify bag labels, count units and match them with booking documents. Moisture or surface contamination is reported and corrected. Customs clearance is processed, then cargo is handed over to the vessel.

Loading strategy matters. Cargo is placed in sections that reduce friction, heat and dust movement. Bulk shipments are carefully compacted to avoid shifting during the voyage.

9. Handing Over Shipment Control

Once containers are sealed and vessel loading is complete, the shipment is officially transferred to the carrier. Buyers receive inspection certificates, packing lists, safety documents and invoices. This closes the refinery to port delivery cycle.

The next stage begins at the receiving terminal, but the foundation of a successful delivery is already built. When every step is managed carefully, sulphur arrives clean, stable and ready for industrial use.

Final Thoughts

Understanding the lifecycle of a sulphur shipment helps buyers see how quality is preserved long before the cargo reaches their port. A disciplined approach reduces risk and ensures that the sulphur they ordered is the sulphur they receive. Get more insights on Gsinfotechvis.

Check us out on LinkedIn.