How Moisture and VM Influence Combustion Losses in Industrial Boilers

Industrial boilers are designed to convert fuel energy into steam or thermal output. When coal properties match burner requirements, plants reach stable heat loads and low fuel consumption. When coal carries excessive moisture or volatile matter, combustion becomes inefficient. Operators burn more tonnes, boilers run hotter, and unburnt carbon increases. Many buyers see moisture and VM as “secondary specs,” but in real boiler rooms they determine daily energy costs.

Understanding how these two parameters influence combustion can help you avoid expensive shutdowns and fuel waste.

Moisture: the silent thief of usable energy

Moisture is not just water attached to coal. It is heat loss waiting to happen. Before coal can burn, the moisture must evaporate. This phase consumes furnace heat, which should have been used to convert water into steam.

How moisture creates losses

◾ Latent heat consumption: energy is spent evaporating water instead of heating the boiler

◾ Lower flame temperature: combustion weakens, impacting steam generation

◾ Increased feed rate: more coal must be consumed to compensate

◾ Condensation risks: moisture can cause corrosion and fouling in ducts

Boilers designed for 5200 GAR fuel will struggle if moisture spikes from 8 percent to 15 percent. Operators push feeder belts harder, fans work overtime and burner adjustments become constant. Instead of smooth heat transfer, plants see fluctuating steam loads.

Moisture also affects handling efficiency

When coal absorbs environmental moisture during transport or port storage, it breaks down into fines. Fines burn quickly, producing spikes in furnace temperature. They escape through chimneys as unburnt carbon and reduce thermal efficiency.

Practical effects on logistics

◾ Flow blockages in conveyors

◾ Segregation in bunkers

◾ Higher dust generation

◾ Inconsistent mill grindability

A shipment that appears cheap on paper becomes expensive when it reaches the boiler room.

Volatile matter: not always good, not always bad

Volatile matter (VM) includes gases and hydrocarbons released when coal is heated. High VM content supports easier ignition and faster flame formation. But when VM is too high, combustion becomes unstable. The burner sees short bursts of energy instead of sustained heat.

General VM behavior

◾ Low VM: slow ignition, longer flame stability

◾ Moderate VM: controlled burn and balanced heat

◾ High VM: quick ignition but uneven flame and soot formation

Industrial boilers need steady combustion to maintain steam output. Excessive VM produces flame shock. Operators see sudden temperature jumps, pressure changes and repeated mill tuning.

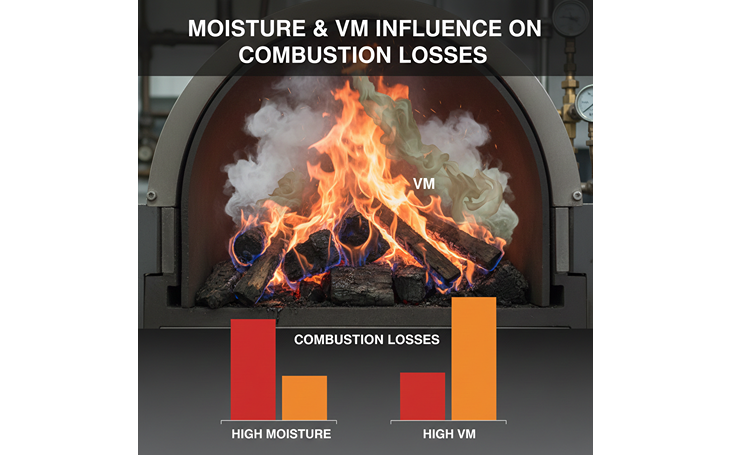

When moisture and VM interact

The most problematic fuel is coal with high moisture and high VM at the same time. The furnace first wastes energy evaporating water, then experiences unstable ignition once volatiles enter the flame zone. Temperature swings fast, and boiler efficiency collapses.

Typical symptoms

◾ High unburnt carbon

◾ Frequent combustion air adjustments

◾ Soot deposits on tube surfaces

◾ Shorter refractory life

◾ Scrubber loads increasing

A plant trying to maintain 32 kg/cm² steam pressure may see dips every hour, forcing operators to overfeed coal.

Why calibration alone is not enough

Combustion engineers can compensate for moisture and VM by changing mill settings, secondary air ratios or burner tilt. But this is treating symptoms. The root cause is fuel mismatch.

Compensating actions come at a cost

◾ More electricity consumed by mill motors

◾ Higher wear on rollers and liners

◾ Frequent burner cleaning

◾ Higher excess air percentage

◾ Boiler trips under load changes

Plants end up spending money on maintenance instead of optimizing fuel cost per tonne of steam.

Upper moisture limits for industrial boilers

Most industrial boiler systems operate best when fuel moisture sits below 12 percent. Beyond this threshold, flame temperature drops and steam generation becomes inconsistent. Some high-efficiency boilers tolerate slightly higher moisture, but only when VM remains moderate and ash chemistry is predictable.

Moisture limits should be part of procurement specifications, not emergency troubleshooting.

VM ranges for stable combustion

Boilers that use pulverized coal generally prefer 22 to 32 percent VM for stable ignition and uniform flame. Very low VM makes ignition difficult, pushing operators to increase secondary air. Very high VM causes intense early flame and reduced downstream heat transfer.

Balance is what preserves boiler life.

Cost of ignoring moisture and VM

The real losses are invisible until they accumulate:

◾ 10 to 18 percent more coal burned

◾ 5 to 12 percent increase in power consumption of milling systems

◾ Frequent scale formation in superheater tubes

◾ More clinker discharge and ash disposal costs

◾ Labor overtime for cleaning and maintenance

A single season of poor-quality imports can destroy annual energy budgets.

How Gsinfotechvis protects buyers from combustion losses

Gsinfotechvis Pvt Ltd does not treat moisture and VM as afterthoughts. The company sources coal from verified regions with stable volatile profiles and controlled moisture. Every shipment is tested and documented to ensure compatibility with industrial boiler systems.

Clients benefit from

◾ Calorific value matched to furnace design

◾ Controlled moisture at loading and transit

◾ Verified VM range for stable ignition

◾ Third-party Q and Q inspections

◾ Logistics planning to avoid rain exposure

◾ Technical guidance for fuel blending

Reliable fuel is the easiest way to reduce combustion losses. Gsinfotechvis helps you move from reactive troubleshooting to preventive performance. If your boiler is consuming more coal than expected, the problem may not be the equipment, but the fuel.

Know more about us on LinkedIn.