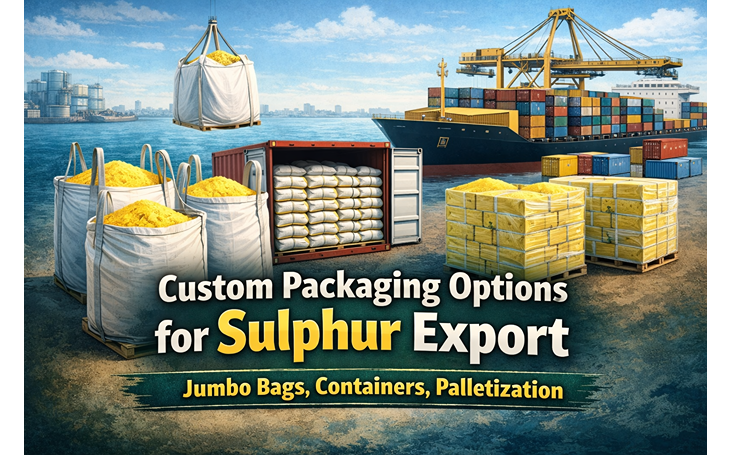

Custom Packaging Options for Sulphur Export: Jumbo Bags, Containers, Palletization

Exporting raw sulphur is not just about sourcing and delivery. The success of a shipment depends on how the material is packaged. Good packaging protects the cargo, keeps workers safe and prevents disruption in customs and port handling. Poor packaging causes dust leakage, contamination, tear hazards and demurrage costs. Buyers who understand packaging options are more likely to receive sulphur in the same condition it left the refinery.

Here are the most effective packaging methods for sulphur export and why they matter.

Jumbo Bags: Reliable and Practical

Jumbo bags, also known as FIBC bags, are the most widely used format for sulphur balls and granules. Their size makes them ideal for bulk shipments without exposing cargo to open environments. Each bag normally holds around one metric tonne or more depending on the specification.

The benefits start with product stability. Sulphur balls flow evenly, settle within the bag and do not puncture walls easily. High quality jumbo bags are built with layered fabric that resists temperature changes, friction and stacking pressure. This reduces breakage during lifting and movement.

Another advantage is clean handling. Jumbo bags reduce dust release during loading and unloading. They are easier for operators to track with labels, barcodes or batch codes. For plants with digital inventory, this packaging format makes inbound management smoother.

Sealed Containers: Maximum Safety for Long Routes

Containerized shipments are common when sulphur is exported over long distances or when weather conditions are unpredictable. Sealed containers reduce exposure to humidity and physical stress. They protect the cargo from sunlight, rain and external contaminants.

Containers are especially useful for ports with strict hazardous cargo regulations. Keeping sulphur sealed prevents accidental ignition from friction or sparks. The cargo remains contained even if a bag is damaged. This reduces clean up costs and insurance complications.

Ship operators often prefer containerized sulphur because movement is predictable and easier to load. Terminal staff can use forklifts and cranes without additional equipment. This speeds up vessel turnaround times and lowers the chance of demurrage.

Palletization: Improving Load Stability

Palletizing jumbo bags or smaller units is an overlooked but valuable step. A pallet base distributes weight across a wider area, which prevents stacking stress. It also keeps the base of the bag off the floor, reducing moisture absorption and abrasion risk.

Pallets make movement simple. Forklifts can load and unload efficiently without touching the product directly. This reduces manual labor, minimizes bag tearing and shortens transfer time between transport modes. For warehouses, palletized shipments require less floor space and are easier to inventory.

Even when large bags are used, palletization prevents tipping and allows more containers to be packed without compromising safety.

Why MSDS Compliance Matters in Packaging

Raw sulphur is categorized as a hazardous material. Packaging must follow guidelines that appear in the Material Safety Data Sheet. An MSDS outlines potential hazards, proper handling, recommended storage temperatures and emergency procedures.

Packaging that aligns with MSDS rules protects not only cargo but also workers. Clear labels, hazard icons and batch numbers allow customs officers, port authorities and shipping companies to verify the product without confusion. This is especially important under IMDG regulations and UN Class 4.1 safety protocols.

Ignoring MSDS guidelines can trigger cargo rejection or repacking at the exporter’s cost. For international buyers, delays at a foreign port can impact production schedules and storage capacity.

Matching Packaging to Project Needs

No single format works for every shipment. A fertilizer company receiving several thousand tonnes may prefer jumbo bags with palletization to keep warehouses organized. A trader moving product across multiple customs zones may choose sealed containers to avoid exposure. Buyers with strict quality standards often mix packaging methods to protect high purity batches.

The best approach is to identify the shipping route, climate conditions, storage environment and unloading equipment before choosing packaging. This prevents last minute adjustments that increase cost.

Final Thoughts

Sulphur packaging is more than a technical detail. It is the foundation of safe, efficient and compliant export logistics. Packaging choices influence cargo performance from refinery gate to final delivery. When selected with care, they help buyers protect their supply and keep operations running without interruption. Get more insights on Gsinfotechvis.

Check us out on LinkedIn.